13 May Single Shaft Conditioner

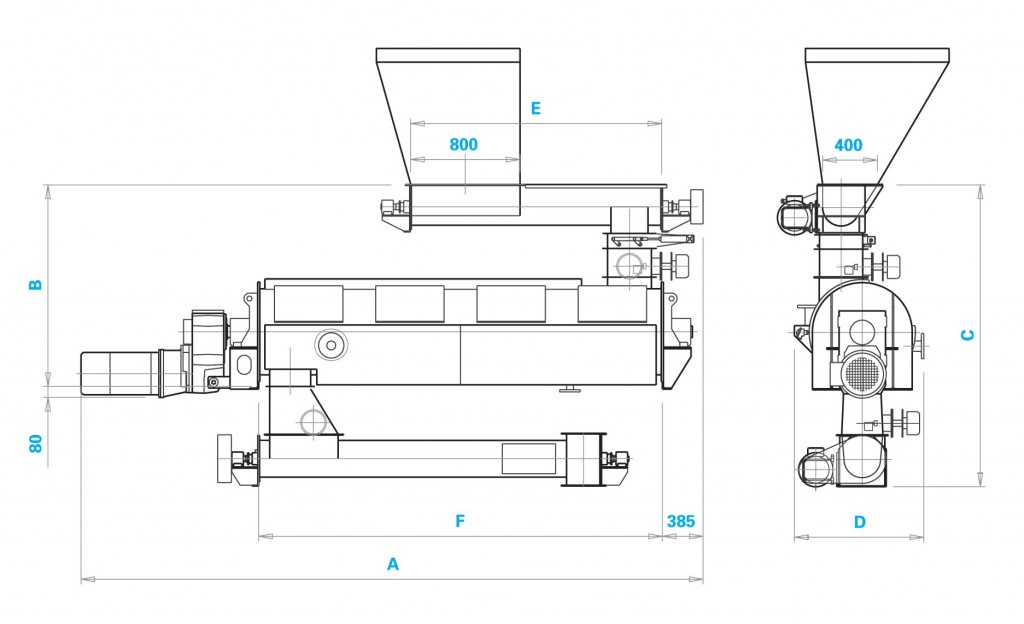

| Model | A | B | C | D | E | F | Capacity [ton/h] | Real volume [m3] | Sppecific weight [kg/dm3] | Perm. time [min] | Power [kw] | Weight [kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CM 8/35 | 5300 | 1660 | 2310 | 1150 | 1835 | 3430 | 18÷30 | 1,46 | 0,5 | 2,5÷1,5 | 37 | 2450 |

| CM 7/30 | 4820 | 1560 | 2210 | 1050 | 1835 | 2950 | 12÷20 | 0,98 | 0,5 | 2,5÷1,5 | 30 | 2050 |

| CM 6/30 | 4630 | 1460 | 2110 | 950 | 1835 | 2950 | 9÷15 | 0,73 | 0,5 | 2,5÷1,5 | 22 | 1850 |

Benefits of thermal treatment and sanitation in animal feed production

– Removal of pathogenic organisms: under certain conditions of time and temperature, destruction of salmonella and other bacteria.

– Increase in the preservation of the feed thus treated.

– Increase in the digestibility of the feed and the conversion factor on the farm.

– Increase in the quality and durability of the pellet.

– Increase the productivity of the pellet mill.

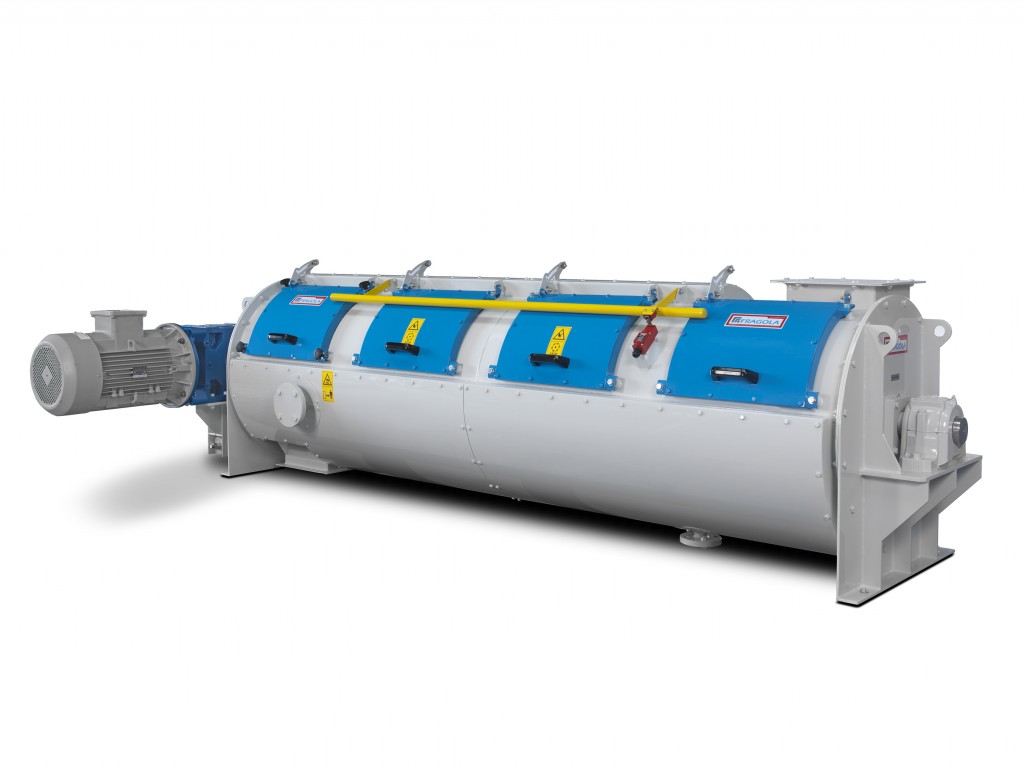

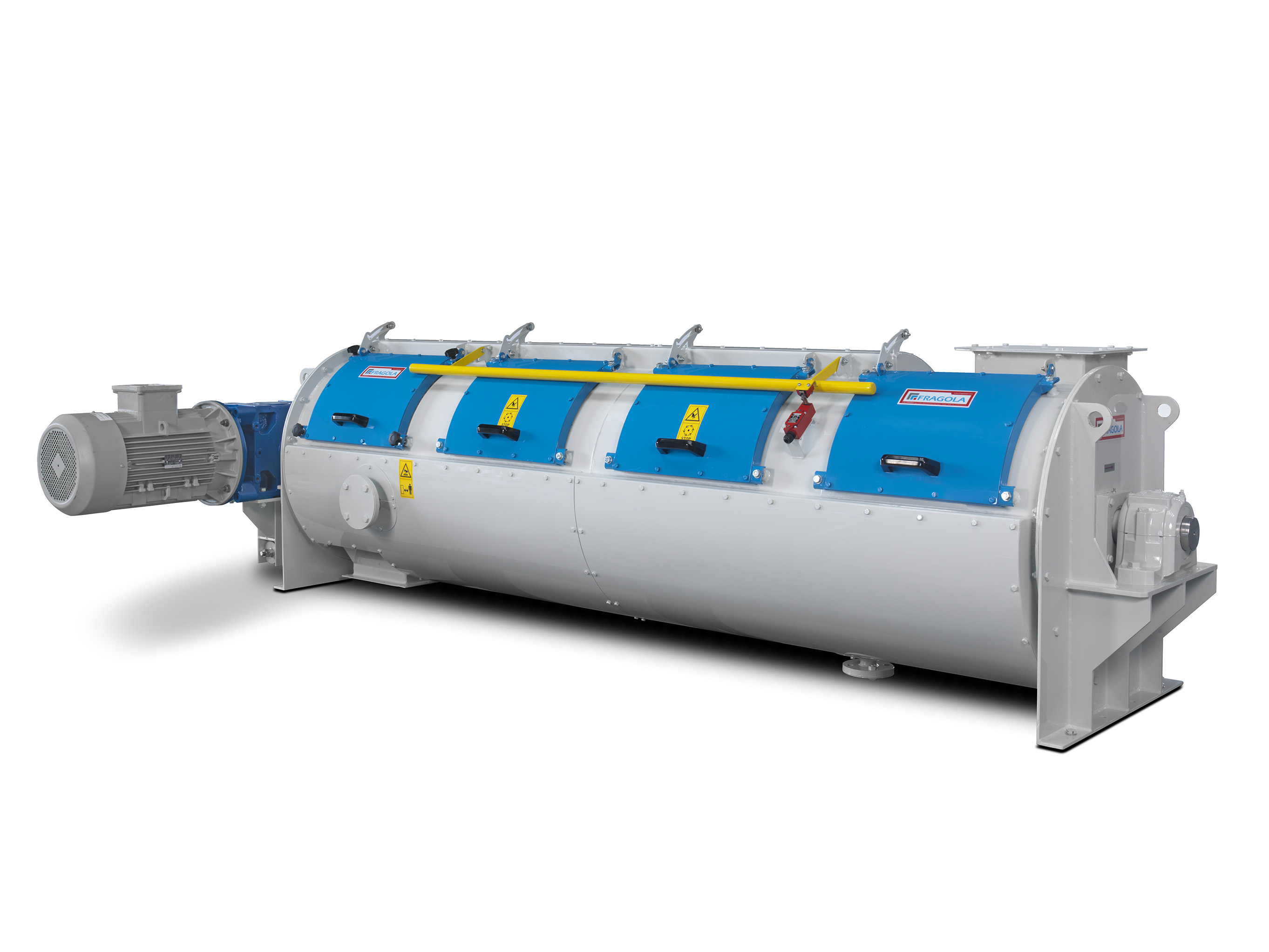

FEATURES OF THE FRAGOLA CONDITIONER

– The Fragola conditioner operates with direct steam, injected directly into the meal, and with the heat transferred from the body of the machine, also heated indirectly with steam.

– Increase in the productivity of the pellet mill from 5% to 15% with insertion of the Fragola conditioner.

– The amount of product entering the conditioner is controlled by a screw feeder.

– Discharge of product from the conditioner is made through a tubular screw which guarantees a constant and optimal load to the pellet mill.

– It is possible to work between 40°C and 95°C in function of the raw material to be treated and the presence of thermolable components, the times of treatment generally vary from 1.5 to 3 minutes.

– The machine is made of stainless steel AISI 304.

– The paddles are bolted and adjustable.